Analysis of the Characteristics and Application Scenarios of Different Types of Thermal Manikins

In the field of human thermal environment simulation and related product testing, thermal manikins are indispensable tools. With technological advancements, various types of thermal manikins have emerged, each with its own unique structure and functionality, suitable for different industry scenarios. Below, we will detail the unique features and applications of various thermal manikins, including dry, sweating, breathing, immersion, and numerical models.

1. Dry Thermal Manikins

Constructive Characteristics

Dry thermal manikins are the most basic type of thermal manikin and are relatively simple in construction. They typically consist of a frame, an insulation layer, and a skin layer. The frame, typically made of metal or high-strength plastic, provides a stable support structure for the manikin, ensuring it remains stable during testing. The insulation layer is often made of high-efficiency insulating materials such as foam plastic and fiberglass, which effectively reduce internal heat transfer to the outside world and maintain a stable internal temperature. The skin layer is made of materials with thermal conductivity similar to human skin, such as special synthetic rubber, to simulate the thermal conductivity characteristics of human skin. Functional Characteristics

The main function of a dry thermal manikin is to simulate the basic heat dissipation of a static human body. Using internal heating devices, such as resistance wires, the manikin is heated to a set temperature and maintained constant, thereby simulating normal metabolic heat production. However, it does not simulate physiological phenomena such as sweating and breathing, and can only provide a relatively simple thermal environment simulation.

Application Scenarios

Dry thermal manikin is often used for preliminary evaluation of the thermal insulation performance of clothing. For example, during the development of winter clothing, designers place the garment on a dry thermal manikin, set the manikin's body temperature, and measure the manikin's heat loss over a certain period of time to determine the garment's thermal performance, thereby optimizing fabric selection and design. Furthermore, in the testing of building insulation materials, dry thermal manikin can be used to simulate the heat dissipation of the human body in indoor environments, assessing whether the insulation performance of building materials meets human thermal comfort requirements.

2. Sweating Thermal Manikin

Constructive Characteristics

The sweating thermal manikin is an upgrade of the dry thermal manikin, with a more complex structure. In addition to featuring a similar frame, insulation, and skin layer to a dry thermal manikin, the system also incorporates a sweating simulation system. This system includes a water reservoir, a water pump, pipes, and tiny pores distributed across the manikin's skin surface. The water reservoir stores simulated sweat, while the pump transports it through the pipes to the pores, allowing it to seep out of the skin like human sweat. Furthermore, to precisely control the amount and location of sweating, the system is equipped with an intelligent control system that allows for flexible adjustments based on testing requirements.

Functional Features

The sweating thermal manikin not only simulates basic human heat dissipation but, more importantly, sweating, a crucial heat dissipation mechanism. By adjusting the amount and location of sweating, it realistically simulates human sweating at varying exercise intensities and ambient temperatures, enabling more accurate testing of clothing's moisture permeability and thermal comfort. Furthermore, it integrates temperature and humidity sensors to monitor real-time temperature and humidity changes on the manikin's surface and within clothing, providing researchers with detailed data support.

Application Scenarios

The sweating thermal manikin plays a key role in the development of sportswear and outdoor equipment. During exercise, the human body sweats profusely, so sportswear needs to have excellent perspiration-wicking and breathability properties. Using a sweating manikin, researchers can test the heat and moisture transfer properties of sportswear made of different fabrics and styles under simulated sweating conditions, thereby optimizing clothing design and improving wearer comfort and performance. In the field of outdoor equipment, such as mountaineering clothing and jackets, sweating manikin can also be used to evaluate the ability of clothing to cope with human sweating in complex environments, ensuring that the equipment provides good thermal and moisture comfort for the user in various climates.

3. Breathing Manikin

Structural Features

The breathing manikin's structure expands upon the sweating manikin's, adding a breathing system. This system includes a breathing pump, a gas pipeline, and a simulated lung cavity. The breathing pump controls the inhalation and exhalation of gas, simulating the rhythm and volume of human breathing. The gas pipeline connects the breathing pump to the simulated lung cavity, and the manikin's head features openings that simulate the mouth and nose to allow for smooth air flow. The Breathing Manikin is also equipped with a gas temperature and humidity control device to simulate changes in gas temperature and humidity during human respiration.

Functional Features

The Breathing Manikin simulates the heat and moisture exchange during human respiration. During respiration, exhaled air carries heat and moisture, which affects the microclimate surrounding the human body. The Breathing Manikin realistically replicates this process by precisely controlling the respiratory rate, respiratory volume, and exhaled air temperature and humidity, enabling testing of the thermal and moisture comfort of clothing while factoring in respiration. Furthermore, it can be used in conjunction with other sensors to monitor temperature and humidity changes caused by respiration on the manikin's surface and within clothing, providing researchers with more comprehensive data.

Application Scenarios

The Breathing Manikin is primarily used in the research and development of specialized clothing and medical protective equipment. For example, in testing medical protective clothing, as medical personnel breathe during work, exhaled air can accumulate inside the clothing, affecting both comfort and protective effectiveness. Using a breathing manikin, researchers can simulate the breathing conditions of medical personnel under varying workloads and test the breathability and impermeability of protective clothing, ensuring that it effectively protects against pathogens while providing excellent thermal and hygroscopic comfort. In the aerospace field, astronauts' spacesuits also need to consider the impact of breathing on the thermal and hygroscopic environment. Breathing manikin can be used to optimize spacesuit design and ensure astronauts' safety and comfort in the space environment.

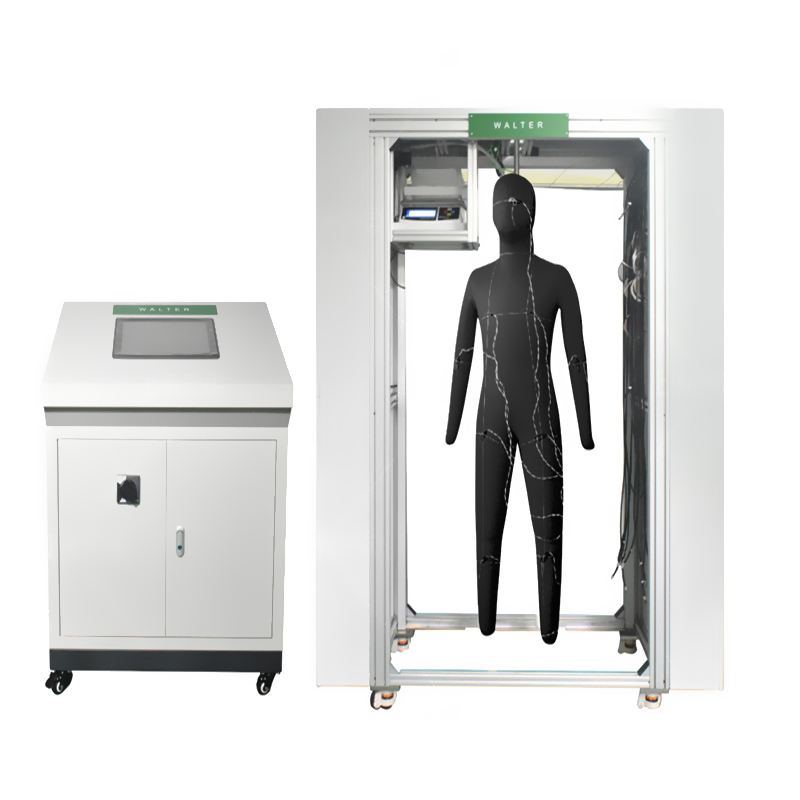

4. Immersion Manikin

Constructive Features

The immersion manikin is designed to simulate the heat exchange of the human body in water. Its construction features exceptional waterproof and thermal insulation properties. The manikin's frame is constructed of high-strength, corrosion-resistant materials such as stainless steel or titanium alloy to resist water erosion. The skin layer is constructed of a waterproof yet elastic material, such as neoprene, to prevent water from penetrating the manikin while simulating the morphological changes of human skin in water. Furthermore, the immersion manikin is equipped with a waterproof heating device and temperature sensor to ensure proper operation and accurate temperature measurement in water. Functional Characteristics

The main function of the immersion thermal manikin is to simulate the heat dissipation process of the human body in water. Water has a much higher thermal conductivity than air, and the body loses heat more rapidly in water. By regulating its internal temperature and simulating different water temperatures, the immersion thermal manikin can accurately measure heat loss from the human body in water. It can also simulate human motion in water to study the impact of motion on heat exchange. It can also be used in conjunction with other equipment, such as a water flow simulator, to simulate heat exchange under different water speeds and directions, providing richer data for research.

Application Scenarios

The immersion thermal manikin is widely used in the research and development of diving equipment and aquatic rescue equipment. Wetsuits must have excellent thermal insulation to prevent hypothermia in cold water. Using the immersion thermal manikin, researchers can test the thermal insulation performance of wetsuits of different materials and designs under various water temperatures, optimizing their structure and material selection. For aquatic rescue equipment, such as life jackets and thermal blankets, the immersion thermal manikin can be used to evaluate their ability to provide warmth and protection in water, ensuring they can effectively protect those in the water in an emergency.

5. Numerical Thermal Manikin

Construction Features

The Numerical Thermal Manikin is not a physical model, but a virtual model constructed using computer simulation technology. It uses mathematical models and algorithms to model the human body's physiological structure, heat transfer processes, and interactions with the environment. The construction of the Numerical Thermal Manikin requires extensive human physiological data, thermophysical parameters, and environmental parameters, along with the use of high-performance computers for complex numerical calculations and simulations.

Functional Features

The advantage of the Numerical Thermal Manikin lies in its flexibility and scalability. It can rapidly simulate the heat exchange processes of humans of varying body shapes and physiological states in various complex environments in a computer, eliminating the need for physical manikin construction and significantly saving time and costs. By varying model parameters, researchers can easily study the impact of various factors on human thermal comfort, such as clothing style, ambient temperature, humidity, and wind speed. Furthermore, the Numerical Thermal Manikin can be combined with other simulation software, such as fluid dynamics software, to conduct in-depth research on air flow and heat and moisture transfer around the human body.

Application Scenarios

The Numerical Thermal Manikin has a wide range of applications in design optimization in the clothing and architectural fields. In the early stages of clothing design, designers can use digital thermal manikins to simulate human thermal comfort under different design scenarios, quickly identifying the optimal design and reducing the costs of physical sample production and testing. In architectural design, digital thermal manikins can be used to simulate human thermal comfort in indoor environments, helping designers optimize the building's ventilation, lighting, and air conditioning systems, improving indoor comfort and energy efficiency. Furthermore, digital thermal manikins can be used in scientific research, providing theoretical support and simulation data for studies of human thermal physiology.

在线客服

在线客服